- INKJET PRINTER RIP HOW TO

- INKJET PRINTER RIP DRIVER

- INKJET PRINTER RIP UPGRADE

- INKJET PRINTER RIP PRO

- INKJET PRINTER RIP SOFTWARE

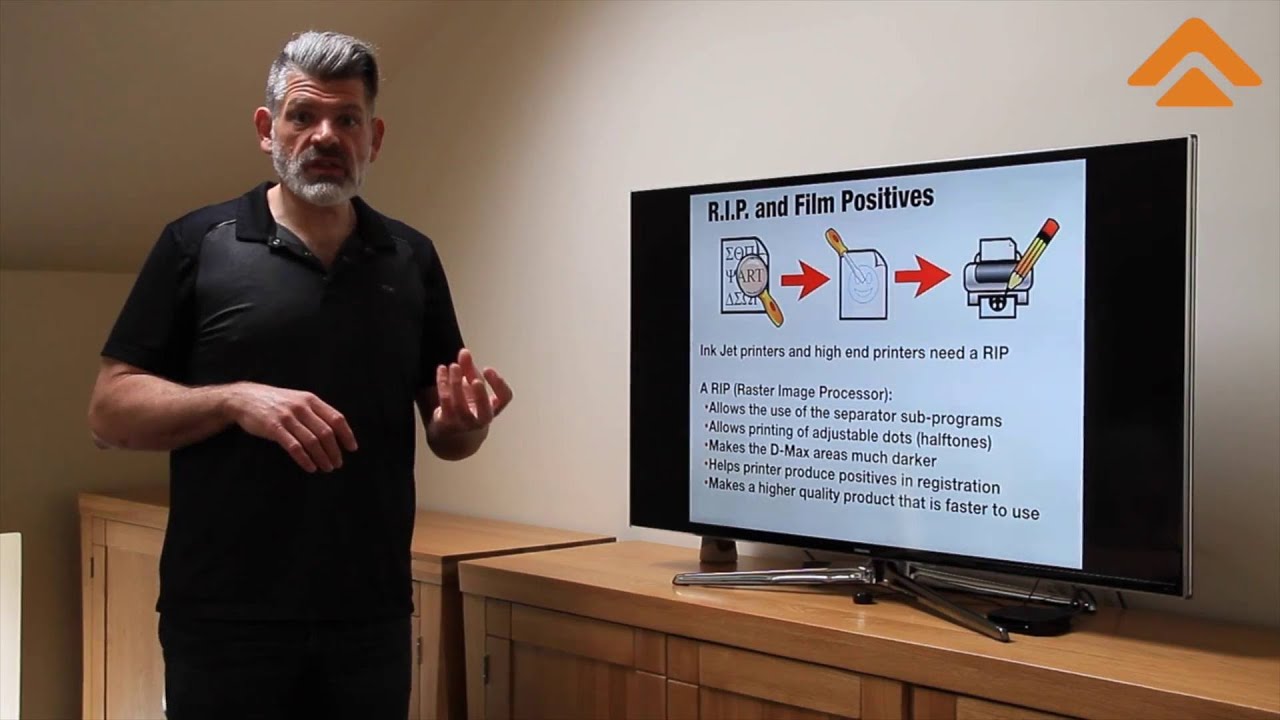

Quick and easy printer, ink, media setup. Easy to set-up, easy to use RIP software. Users can usually pick it up with about 30 minutes of training. FilmMaker is able to provide optimum ink levels using a variety of ink/media combinations. Spectraflow can even provide this service remotely, greatly reducing the on site resources required to keep a fleet of printers in tolerance.įiery XF’s modern user interface is intuitive and “Mac-like”, which contrasts favorably with most other RIPs. This enables the option to recalibrate in an automated fashion. It allows multiple printers to closely match one another as well as stay consistent over time.įiery XF works with printer-integrated spectrophotometers from Epson, HP and Canon. EFI uses a sophisticated recalibration utility that measures a wide variety of colors and creates a 3D lookup table. And if you add in drift over time, it can be very challenging to consistently get the same results from multiple printers. Similarly, there is often a noticeable printer-to-printer variation. While most inkjet printers come out of the factory behaving pretty The Nesting function automatically gangs up jobs to minimize paper usage. Some of the functionality of the RIP such as job-queue monitoring, cropping, scaling, auto-rotate (to minimize paper usage) improve productivity.

INKJET PRINTER RIP DRIVER

This greatly simplifiesĪchieving consistent and accurate color in a multi-user environment, since there’s no need for each user to choose the correct profile and driver settings each time they make a print. Good for IT – the server can be placed in a controlled area and a high RIP-to-printer ratio requires IT to maintain fewer RIP stations.Īll color management settings are set in the RIP. It is a brilliant combination of the MACH 6 digital color printer and mColor, our one-of-a-kind color management software. Our M Series Printing System boosts us above the competition. Client can be used in mixed environment of Mac and Windows users. RENA by Quadient is the leading provider of tabletop inkjet address printers for the professional mailer. Their desktop instead of having to walk over to a RIP station. Good for end users - allows them to monitor and control their jobs from

INKJET PRINTER RIP HOW TO

Because BEST is a complex high-end RIP for commercial prepress shops who know how to use a spectrophotometer, it always helps to get your printer, scanner, RIP, ICC software, inks, and. Originally the company was German, but it was recently sold to EFI, Electronics for Imaging.

Maintop software, color electric publishing system V5.3, is one of the most widely used inkjet. BEST is a well known color management RIP for wide format printers.

INKJET PRINTER RIP SOFTWARE

That we always use RIP printout software is Maintop software in most of China domestic Eco solvent printers and inkjet printers.

INKJET PRINTER RIP UPGRADE

This also helps reduce ongoing maintenance and upgrade costs. 84 What Format Picture Should Be Saved For Printing With Inkjet Printer With Maintop RIP 84. One RIP station can drive upwards of five printers, leading to lower upfront costs than other RIP packages. A RIP raster image processor saves time and will make a remarkable impact on your color management workflow High Speed / Low Cost:įiery XF is 64-bit native and multi-threaded, which means it can process a lot of jobs very quickly. RIP printing software offers more control and capabilities to your commercial printer’s workflow. Fiery XF has a number of advantages that provide benefits over printing through the manufacturer’s driver or through other RIP packages. – including Abercrombie & Fitch, Mattel, Pixar Animation Studios, Kohl’s Department Stores,

INKJET PRINTER RIP PRO

The cost is simply that of an Epson Stylus Pro high quality inkjet printer using standard UltraChrome K3/HDR inks combined with a RIP. JT Direct Inkjet plates provide the lowest cost of ownership compared to any existing CTP system in its class. Affordable, Versatile and User-Friendly CTP Solution Offering run lengths up to 20,000 impressions, the JT aluminum plate is designed to be imaged on a standard Epson inkjet printer using standard inks. The Presstek JT Direct Inkjet Plate enables for a low-cost, simple plate production solution that provides pleasing color every time. JT Direct Inkjet Plates Eco-Friendly, Offset Quality, Digital Simplicity

0 kommentar(er)

0 kommentar(er)